User blogs

Laser pointer wholesale in kitlaser

We have shown that a powerful directed energy laser is now sufficiently light-weight, low volume and reliable enough to be deployed on tactical vehicles for defensive applications on land, at sea and in the air," said Robert Afzal, senior fellow for Laser and Sensor Systems at Lockheed.It can receive inputs over the network connection, so up to four devices can project content at the same time. There are quite a few targets 60-100 kW green laser pointer could be used to degrade or defeat, including rockets, artillery rounds, some missiles, UAVs (Unmanned Aerial Vehicles), etc.,” Gunzinger told me in an email. “We are talking short ranges for ground-based 100 kW-class lasers to achieve ‘burn-through’ kills on UAVs or rockets, (but) sometimes a functional kill — blinding or burning out a sensor a weapon uses for final guidance to a target — is good enough.There’s Bluetooth as well, but that’s just for streaming audio."

"And it's been able to prove itself over the last three years as being incredibly effective at that."The new laser system could have some limitations in its effectiveness, according to Alexei Leonov, a military expert and commercial director of Arsenal Otechestva.“The longer the distance to target, the weaker the laser beam becomes, and at long distances it becomes useless altogether.”The resolution is 4K, but it also supports HDR. Some would claim that makes a bigger difference than simply bumping the resolution.Dell further claims that this projector has a high enough output that it can be used in daylight conditions. So, no heavy curtains required. Today, the 2000mW laser pointer is intended primarily to disable or destroy aircraft and small boats. "It's designed with the intent of being able to counter airborne and surface-based threats," said Hughes.

MapSmart is designed for any forestry, construction or GIS professional who needs to quickly and accurately map, measure, or position features such as trees, street furniture or even telephone and powerline poles. It’s a simple yet powerful program that easily integrates with LTI’s TruPulse and TruPoint laser devices that makes a total data collection solution.Did you have it? If you do not, I recommend you a laser pen, this laser pen has two colors, red 200mw output, purple 100mw output, cheap, small, mini flashlight design, easy to carry, is worth the type you are, you still And so on, quickly enter kitlaser to buy it, not as good as action! Here, you will enjoy the best quality service and products, so you buy the rest assured that the use of peace of mind!Optimized to measure highly reflective target surfaces, the new S300 represents a breakthrough in high end blue laser pen sensor technology.

This program was specifically designed to be easy to operate so more time can be spent mapping and collecting data rather than extensive training. Only one GPS coordinate is needed to map surrounding features or landmarks because they can all be mathematically calculated based on that one collected latitude and longitude position established as the origin point. Today, more and more popular laser pen, the use of laser pen more and more people, laser pen has become a necessity for people.With features such as a low-gain diode and an optional lens kit, the TruSense S300 is designed to increase reliability, accuracy and repeatability while decreasing random noise associated with the properties of many fluids.

Professionals can choose to use the Android device’s GPS to establish their occupied position for remote offset mapping or can use high-accuracy Bluetooth GPS or can choose to not use GPS at all.This makes them well suited for measuring fluid levels in tight spaces such as pumping stations with deep wells and exposed pipes. They can also operate through protective screens and near walls. For high temperature and high pressure vessels, 100mW laser pen sensors can be mounted using a sight glass. Laser sensors can also be used with stilling tubes. Because of the laser’s narrow beam width and independence from dialytic properties, stilling tubes can be made much simpler and less expensive than when using radar or ultrasonic sensing technologies.The software also includes a complete volumetric calculation solution a no additional charge.Laser sensors can be installed at the top of a vessel for easy installation, access and maintenance.

http://www.kitlaser.com/multiple-colour-2000mw-blue-beam-laser-pointer.html

http://www.kitlaser.com/100mw-red-beam-black-shell-pen-single-point-laser-pen.html

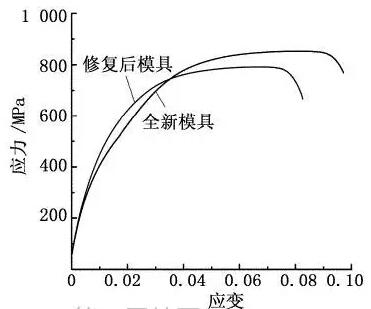

The mold repair and maintenance of A-MAX steel die with crack and wear were carried out by laser welding, and the microstructure, tensile property and fatigue property of the die were analyzed. The results show that there are fine lath martensite and some white ferrite structures distributed along the grain boundary in the weld zone of the high power laser pointer welding joint. The HAZ of the joint is ferrite and pearlite. After laser welding of the mold tensile strength and elongation of the new A-MAX mold 93.95% and 88.92%, and the repair of the fatigue life of the mold has been significantly improved, and the new mold fatigue cycle times in the same order of magnitude.

Mold manufacturing with the rapid development of industrial technology and expanding, in the modern manufacturing industry, especially in the field of precision manufacturing to obtain a wide range of applications, can effectively improve the utilization of materials and extend the service life of the product. With the rapid development of die-casting industry, die-casting molds on the overall mechanical properties and service life of higher demands, and because of the high cost of die-casting molds, molds in the long-term use conditions due to high-speed, high pressure, alternating hot or cold The working environment of the load causes the mold surface or the internal appearance corrosion, the wear or the crack causes the mold performance to drop, may even cause the mold to fail. The manufacture of molds involves the selection of materials, complex precision machining and associated heat treatment systems, which are expensive to manufacture and long in cycle time. Therefore, in order to avoid the mold due to cracks or wear and other forms of failure affecting production, and the use of mold repair welding technology, the technology is a die surface to solve the direct and effective method. Laser welding technology as a high-power density, energy concentration, the loss of welding consumables is small, and easy to automate the efficient high-precision welding, can achieve large penetration depth, low residual stress and deformation of the welding components, so laser pointer repair mold welding technology Because of its low cost, short cycle, good repair effect and become a common mold repair welding technology to overcome the cold welding and welding in the repair of fine mold surface defects.

Test conditions: The object of the study is a cracked engine block die casting mold. The mold material is A-MAX steel. It is refined by vacuum electroslag remelting process. The hardenability is good. The service life is 3-5 times of SKD61 steel. The crack depth is 40% lower than that of SKD61 steel. The steel has excellent resistance to cracking, high temperature toughness, high temperature strength, fire resistance and high temperature strength properties for a variety of large, complex die-casting molds. During the test, acetone or absolute ethanol was used instead of industrial cleaners for surface cleaning prior to welding. Repeated cleaning was necessary to meet the welding requirements because incomplete cleaning or secondary contamination could eventually lead to a significant reduction in repair quality .

Test equipment: laser welding equipment using SLC CNC laser multi-function machine, power 5KW, wavelength 10.6μm, the minimum spot diameter of 0.12mm, welding speed of 1m / min, shielding gas for argon.

Test method: Tensile test was carried out by using HY-932 tensile testing machine. According to GB / T 228-2002 standard, the total length of tensile specimen is 200mm, segment length is 95mm, radius of arc is 20mm, test temperature is Room temperature. The fatigue properties of the joint were tested with QBG-25 high frequency fatigue tester. The fatigue specimen was made according to GB / T 2015111-1994. The stress ratio of cyclic stress was 0.1 and the frequency was 100Hz. In order to reduce the test error, two samples of each parallel test.

Test results and analysis: can be seen from Figure 1, the center of the weld between the two plates in the phase plate. Because the base material is austenite and ferrite, the middle of the weld is fine grain structure, and the fusion zone is columnar. Because burning laser pointer welding has high peak temperature, faster welding speed and cooling rate, The heat affected zone of the laser welding of the -MAX steel mold is very small, but it can be seen that the microstructure of the heat affected zone of the joint in the mold repair is white ferrite and black pearlite structure. As can be seen from Figure 1b, A-MAX steel weld microstructure is relatively small quenching organizations, but also observed a small lath martensite and some along the grain boundary distribution of white ferrite. In addition, there is a small amount of fine precipitates in the welds of the A-MAX steel, which improves the strength of the A-MAX steel molds. Because the energy density of the laser beam is concentrated during the laser welding process, and the welding speed of the 50mw laser pointer is relatively fast, the liquid metal in the joint melting zone will solidify at a faster cooling rate, which is equivalent to a once Rapid hardening process, get the strength, hardness and plasticity of good lath martensite structure.

The left figure shows the results of comparison of the tensile strength and elongation of the new mold. The tensile strength of the new A-MAX mold is 843MPa and the elongation is 9.419%. The tensile strength of the A-MAX mold is 792MPa and the elongation is 8.375%. After the repair, the tensile strength of the mold reaches new A-MAX 93.95% of the mold, the elongation of the new mold also reached 88.92%. It can be seen, after 5mw laser pointer welding repair hot work die welded joints tensile strength and elongation are very close to the new A-MAX mold, with better mechanical properties. The reason for the weld strength at the mold repair site is close to the A-MAX steel base material, because the mold repair site is the highest energy and temperature zone in the laser welding, resulting in the welding zone in the welding direction is greater than the welding temperature Ac3 line temperature, and A-MAX steel quenched and tempered composition was more evenly distributed. So that at high temperature conditions, carbon and other alloying elements can be fully diffused, easy to obtain a uniform composition of austenite organizational structure. In addition, the green laser pointer welding speed is faster, and then the weld zone will melt rapidly at a rapid rate of cooling down, and finally the formation of regularly arranged carbon-lean lath martensite and a small amount of residual ferrite, and by laser welding , The lath martensite structure obtained by welding joint is more fine.

The figure on the right is the results of fatigue tests on two specimens tested on a QBG-25 high-frequency fatigue tester. Sample 1 and Sample 2 are fatigue samples of the restored mold, and Sample 3 and Sample 4 are fatigue samples of the new mold. It can be seen that the number of fatigue cycles of sample 3 is the largest, and the average of two tests is 20619 times. The average number of fatigue cycles of A-MAX mold 1 and sample 2 is 17322 times, 83.69%. It can be seen, the mold is about to scrap the use of laser repair welding after the high-frequency fatigue life is improved, close to the new A-MAX mold, and with the new mold fatigue cycle has been in the same order of magnitude.

The microstructures of HAZ are ferrite and pearlite microstructure, and the microstructures of the joint HAZ are ferrite and microstructures. The tensile strength and elongation of the hot work die were 93.95% and 89.92% of that of the new A-MAX mold, and the mechanical properties of the mold after the repair were close to that of the new A-MAX mold. After 2000mw laser pointer welding repair Thermal die fatigue life of about 83.69% of new mold, with the new mold fatigue cycle has been an order of magnitude.

http://socialenginepro.com/demo_i_love_metro/blogs/11020/17946/the-best-currently-available-hom